Our guns are designed with the shooter in mind

The creation

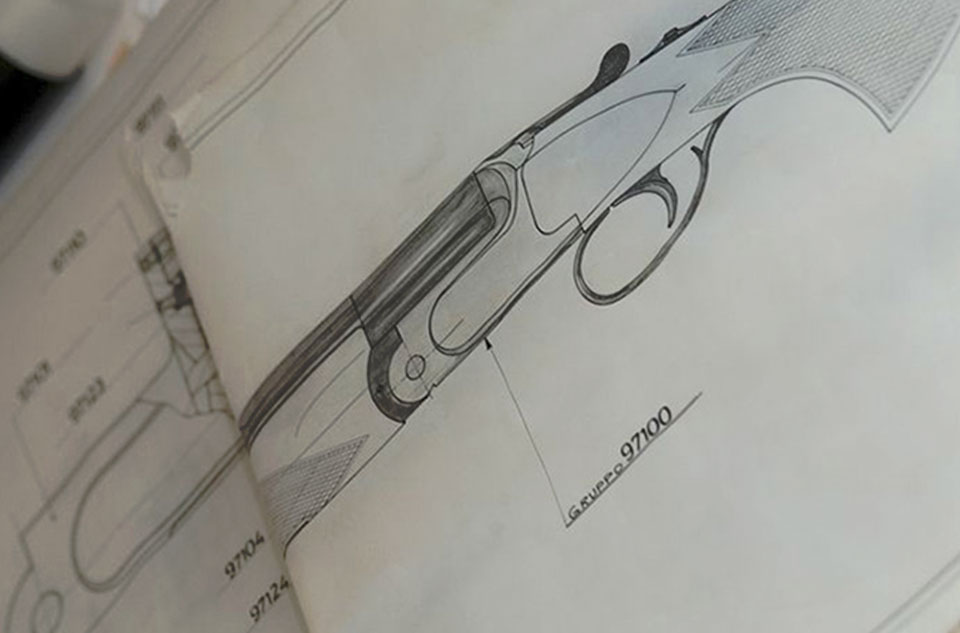

In designing the Salvinelli guns, the starting point was to make a platform, that after all options have been selected, we can every time arrive at a gun that is just right for our clients. The many versions of the gun share a common platform, making for a versatile and reliable starting point. Each client can then choose from a list of different options to create a gun as individual as they are themselves, laying the foundations for the creation of a fine handcrafted instrument and a true personal possession.

by master craftsmen

Manufacturing methods

Salvinelli guns feature the optimum combination of fine artisan craftsmanship and modern CNC machining techniques.

While the receiver block, the monoblock, the top lever and the fore arm iron are milled into shape by CNC machines, thus guaranteeing a repeatable process with respect to the dimensions of parts that require precision that is beyond human capability, the rest of the gun is made, fitted, and finished by hand.

All engraved models are hand engraved and signed by master craftsmen.

Relevance of design

The evolution in materials

Insofar as competition guns go, detachable trigger groups were previously viewed as a must. This was at a time when trigger groups of competition guns were equipped with somewhat fragile flat springs. With coil springs, featuring greater durability and long life spans, becoming increasingly the norm in competition shotguns, the risk of spring failure has been reduced greatly. Consequently, the requirement for a detachable trigger group and the resulting larger receiver dimensions necessitated by the wider trigger plate have been concomitantly reduced.

Receiver

The sculpted receiver of Salvinelli guns and the non-detachable trigger group allow for a sleeker receiver profile without any compromise in the strength of the receiver. The result is a gun that feels extremely solid without suffering from an overly weighty mid-section. This in turn allows the distribution of weight along the gun as per client wishes.

Locking system

The locking system is a modified Boss – inspired lockup, featuring large locking lumps on the bottom of the receiver and the reciprocal recesses on the barrel lump. These, combined with the large locking claws on both sides of the monoblock, the overall construction results in a very solid lockup with no transfer of shot-induced stress to the trunnions.

Barrels

Our barrels are cold hammer forged for maximum strength with the bores hard chromed for corrosion resistance. With respect to artistic appeal, we offer receiver and parts finishes in traditional blued, hard chrome, as well as case colored finishes. The engravings in the "models" section are to offer guidance as to the type and degree of fullness of engraving that befits each model. However, for Models EXO and higher, we naturally welcome any motifs the client may have in mind.

In design, production, delivery and service

Improvement

While Salvinelli guns may not come up with catchy new monikers for the forcing cone configuration, choke system or barrels or "brand new" guns that are in fact old guns with minor changes, we hone our design and production processes continuously.

We openly solicit client feedback on all aspects of our guns and endeavor to investigate any client suggestions promptly and respond to them as deemed appropriate. Upon the receipt of your gun, we welcome any suggestions you might have about how we can better serve our existing and future clientele.

Our guns may not change much in appearance over time. However, internally we have developed all aspects of the gun to continually improve the design over time. We also aim to increase the efficiency of production without sacrificing quality.

We understand that the anticipation of taking delivery of your gun is part of the pleasure, but we don’t want to prolong this anticipation further than necessary.